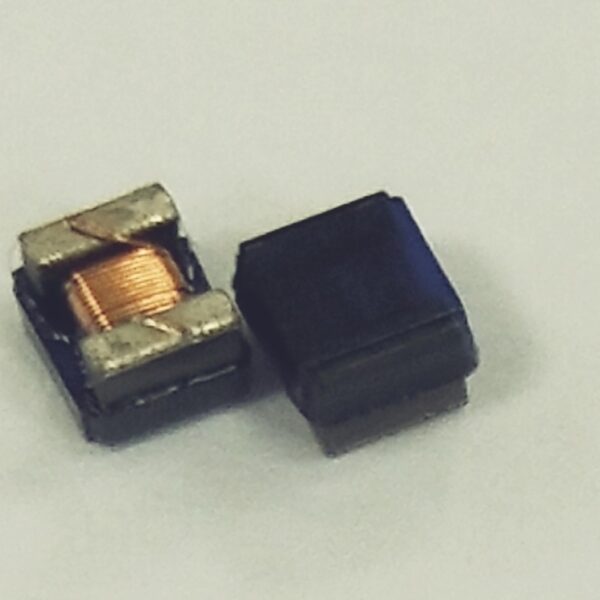

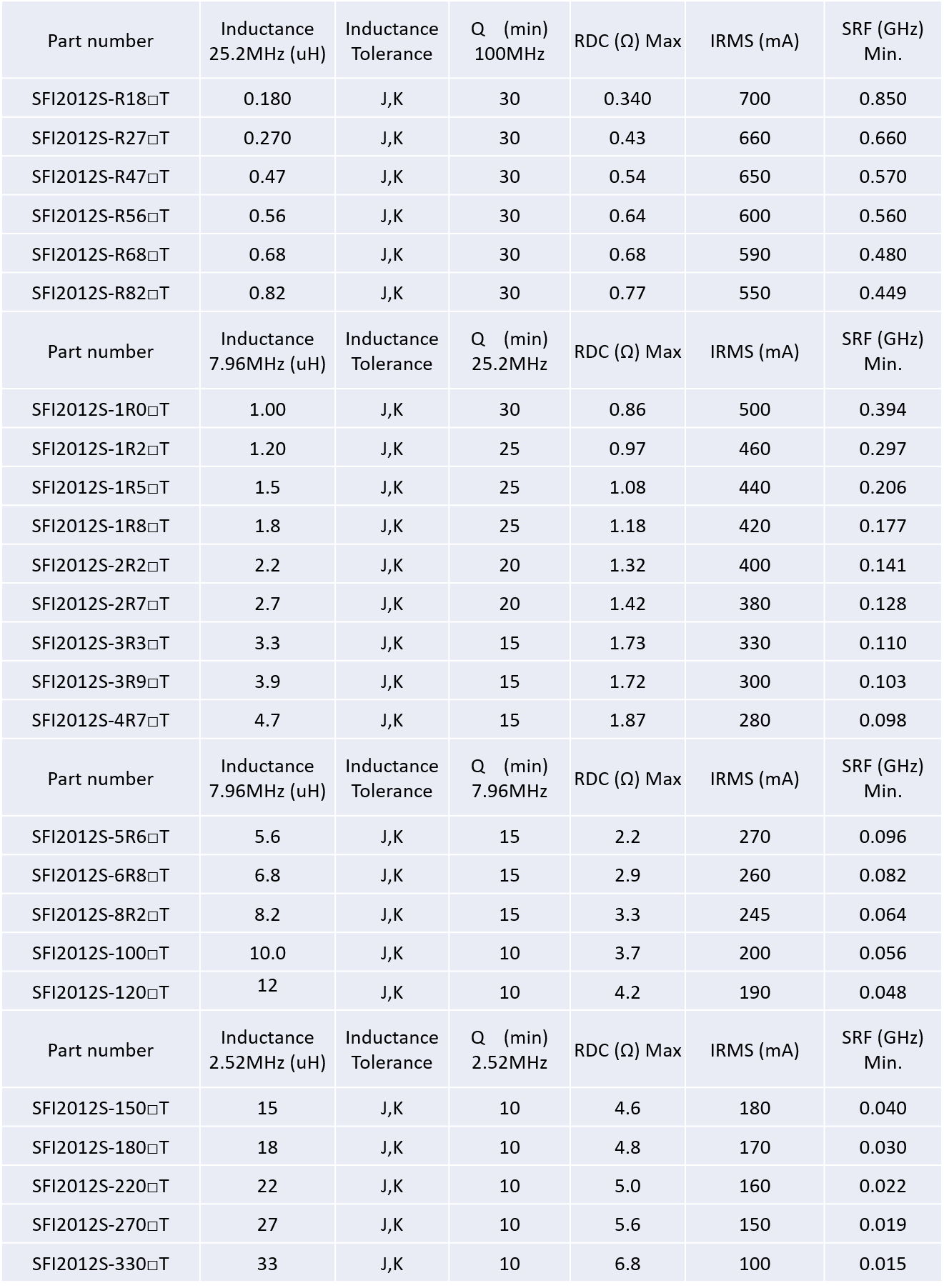

Description

Features & Application

• Higher inductance values than other 0805 inductors

“• Ferrite construction for high current handling”

• Inductance values: 0.18H – 33 µH; 10%and 20% tolerance

Core material Ferrite

Environmental RoHS compliant, halogen free

Terminations Silver-palladium-platinum-glass frit. Other terminations

available at additional cost.

Ambient temperature –40°C to +125°C with Irms current

Maximum part temperature +140°C (ambient + temp rise).

Storage temperature Component: –40°C to +140°C. Tape and reel packaging: –40°C to +80°C

Resistance to soldering heat Max three 40 second reflows at +260°C, parts cooled to room temperature between cycles

Temperature Coefficient of Inductance (TCL) +25 to +125 ppm/°C

Moisture Sensitivity Level (MSL) 1 (unlimited floor life at <30°C / 85% relative humidity)

Impedance/Inductance/Q/ LCR Angilent E4991A

Resistance DC Chroma 16502

Current per winding that causes a 20°C rise from 25°C ambient

Electrical specifications at 25°C

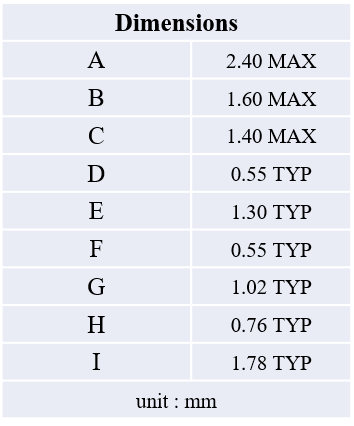

Weight 10.7 – 12.2 mg.

Packaging 2000/7″ reel; Plastic tape: 8 mm wide.

Packaging will different,accroding the various chip size.

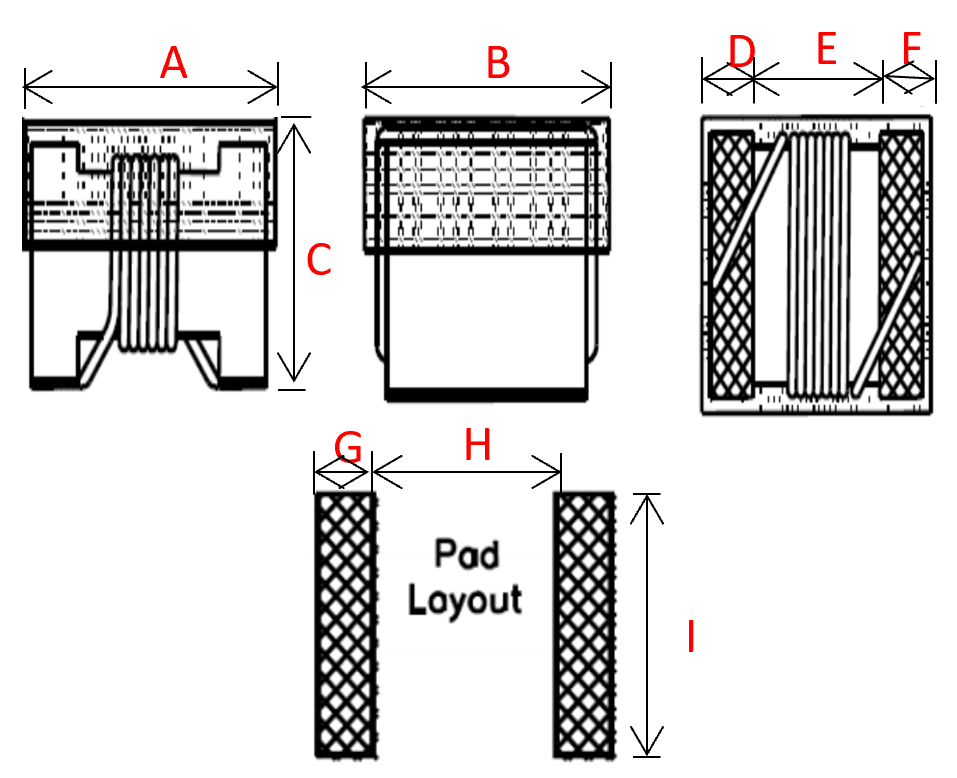

Typical Inductance vs Frequency

GENERAL CHARACTERISTICS

1. Operating temperature range: -40 TO + 125℃(Includes temperature when the coil is heated)

2. External appearance: On visual inspection, the coil has no external defects.

3. Terminal strength: After soldering. Between copper plate and terminals of coil. Push in two directions of X.Ywithstanding at below conditions.

Terminal should not peel off. (refer to figure at right) 0.5kg Min –2012

4. Insulating resistance: Over 100MΩ at 100V D.C. between coil and core

5. Dielectric strength: No dielectric breakdown at 100V D.C. for 1 minute between coil and core

6. Temperature characteristics: Inductance coefficient (0~2,000)x10-6/ ( ℃ -25~+80 ). ℃ , inductance deviation within±5.0%, after 96 hours.

7. Humidity characteristics(Moisture Resistance): Inductance deviation within ±5%, after 96 hours in 90~95% relative humidity at 40 ±2 and 1 hour drying under normal condition.

8. Vibration resistance: Inductance deviation within ±5%, after vibration for 1 hour. In each of three orientations at sweep vibration (10~55~10 Hz) with 1.5mm P-P amplitudes.

9. Shock resistance: Inductance deviation within ±5%, after being dropped once with 981m/s2 (100G) shock attitude upon a rubber block method shock testing machine, in three different orientations.

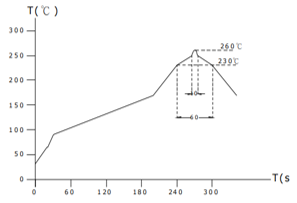

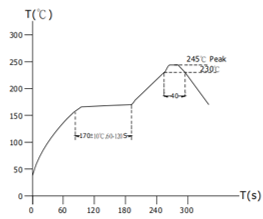

10. Resistance to Soldering Heat: 260 , 10 seconds(See attached recommend reflow)

11. Storage environment: Storage condition: Temperature Range: 10 ~ 35 (Generally: 21 ~ 31 ) , Humidity Range: 50% ~ 80% RH (Generally: 65% ~ 75%) ; Transportation condition: Temperature Range:-35 ~ 85 , Humidity Range: 50% ~ 95% RH

12. Use components within 12 months. If 12 months or more have elapsed, check soldarability before use.

13. Reflow profile recommend:

Lead-free heat en duran ce test

Lead-free the recommended reflow condition

Additional information

| 型號 | SFI2012S-R18KT, SFI2012S-R27KT, SFI2012S-R47KT, SFI2012S-R56KT, SFI2012S-R68KT, SFI2012S-R82KT, SFI2012S-1R0KT, SFI2012S-1R2KT, SFI2012S-1R5KT, SFI2012S-1R8KT, SFI2012S-2R2KT, SFI2012S-2R7KT, SFI2012S-3R3KT, SFI2012S-3R9KT, SFI2012S-4R7KT, SFI2012S-5R6KT, SFI2012S-6R8KT, SFI2012S-8R2KT, SFI2012S-100KT, SFI2012S-120KT, SFI2012S-150KT, SFI2012S-180KT, SFI2012S-220KT, SFI2012S-270KT, SFI2012S-330KT |

|---|

Model

★ When ordering, please check part number

Isolation (Vrms) : 250V. Winding to winding isolation (hipot) tested for one minute.